GD&T MEASUREMENT AND ALIGNMENT

Axist SRL offers comprehensive on-site 3D measurement services, utilizing advanced laser trackers and articulated arms to assess various Geometric Dimensioning and Tolerancing (GD&T) characteristics. This enables clients across diverse industries to receive prompt and precise solutions to their dimensional challenges.

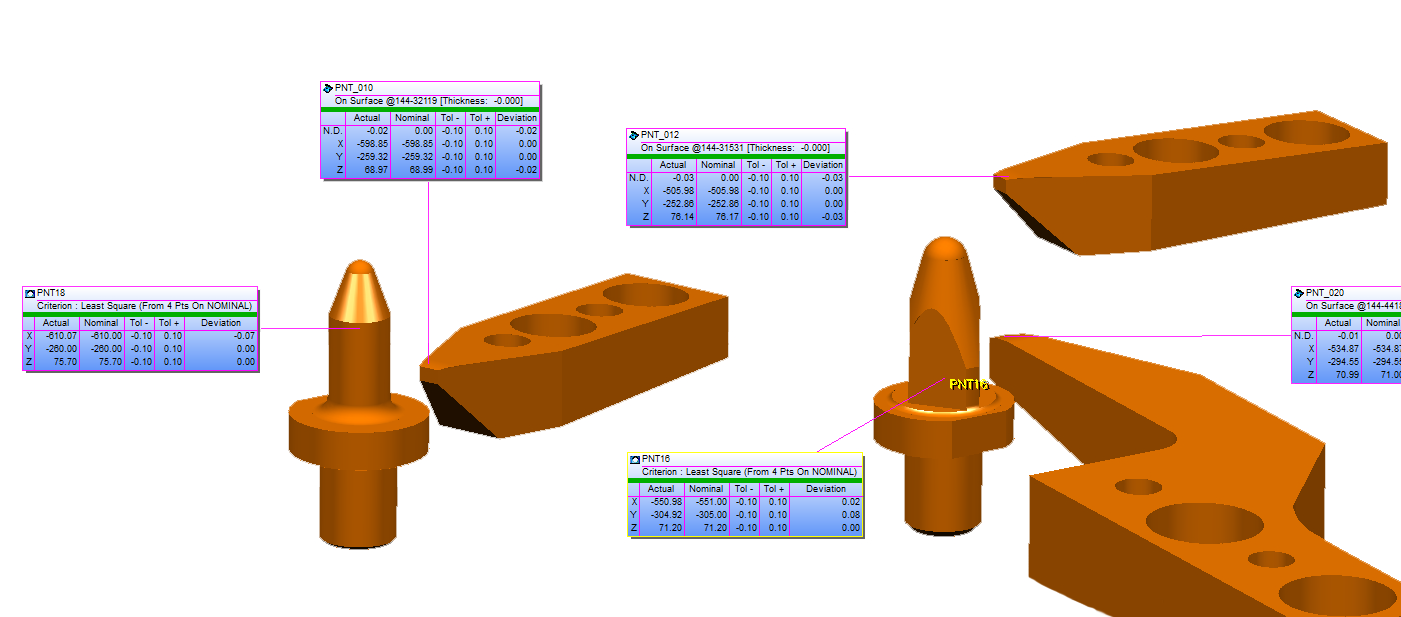

GD&T 3D Features Measurement

By meticulously evaluating these GD&T characteristics, Axist ensures that mechanical parts and assemblies meet stringent quality standards, providing clients with fast and accurate assessments to address their dimensional challenges effectively.

Employing laser trackers and articulated arms for these measurements enhances accuracy, reduces errors, and improves overall efficiency in shipbuilding processes.

Key GD&T Characteristics 3D Measured by Axist

SERVICE INFO

Since 2006 we have worked with most European Automotive Integrators, in various locations, starting from the first single parts manufactured by the suppliers, to Jigs and Fixtures 3D Measurement on suppliers’ sites, to the final assembly line adjustment.

Axist puts our laser trackers and articulated 3D measurement arms, state of the art inspection software and almost 20 years of experience at your service.

NORMAL HOURS

| Week Days | 7:00 – 20:00 |

| Saturday | 8:00 – 16:00 |

| Sunday | Generally Off |

We understand the importance of delivering on time. We have been very flexible with our work schedule since 2006, working flexible hours and shifts.

Advanced Technologies Employed:

3D INSPECTION SERVICES BY INDUSTRY

Axist is a company specializing in 3D dimensional services on the client’s premises. Our goal is to support clients with dimensional inspection services at the highest standards using the most accurate portable metrology equipment.

We gained our experience in 3D dimensional control services by working in various industries across Europe, Asia and Midlle East.